Mainstream ceramic capacitor product series parameters

Mainstream Ceramic Capacitor Product Series Parameters

I. Introduction

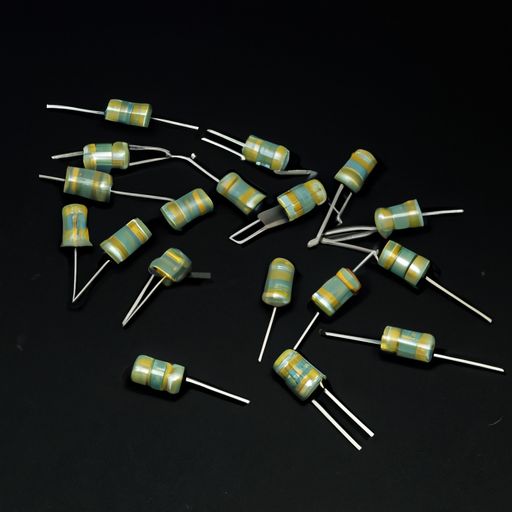

A. Definition of Ceramic Capacitors

Ceramic capacitors are passive electronic components that store electrical energy in an electric field. They are made from ceramic materials, which serve as the dielectric medium between conductive plates. These capacitors are widely used in various electronic circuits due to their reliability, stability, and versatility.

B. Importance of Ceramic Capacitors in Electronics

Ceramic capacitors play a crucial role in modern electronics. They are essential for filtering, decoupling, and energy storage in a wide range of applications, from consumer electronics to industrial machinery. Their ability to maintain performance across a wide range of temperatures and frequencies makes them indispensable in circuit design.

C. Overview of the Article's Purpose

This article aims to provide a comprehensive overview of the parameters associated with mainstream ceramic capacitor product series. By understanding these parameters, engineers and designers can make informed decisions when selecting capacitors for their specific applications.

II. Types of Ceramic Capacitors

A. Class 1 Ceramic Capacitors

1. Characteristics

Class 1 ceramic capacitors are known for their stability and low loss characteristics. They typically use materials like C0G (NP0) and are characterized by a linear capacitance change with temperature. These capacitors have low dielectric losses and are suitable for high-frequency applications.

2. Applications

Class 1 capacitors are commonly used in timing circuits, RF applications, and precision analog circuits where stability and accuracy are paramount.

B. Class 2 Ceramic Capacitors

1. Characteristics

Class 2 ceramic capacitors, such as X7R and Y5V, offer higher capacitance values but with less stability compared to Class 1. They exhibit a significant change in capacitance with temperature and voltage, making them less suitable for precision applications.

2. Applications

These capacitors are widely used in decoupling, filtering, and energy storage applications in consumer electronics, automotive systems, and power supply circuits.

C. Comparison of Class 1 and Class 2

The primary difference between Class 1 and Class 2 ceramic capacitors lies in their stability and capacitance values. Class 1 capacitors are preferred for applications requiring precision, while Class 2 capacitors are chosen for their higher capacitance values and cost-effectiveness.

III. Key Parameters of Ceramic Capacitors

A. Capacitance Value

1. Measurement Units (Farads, Microfarads, etc.)

Capacitance is measured in Farads (F), with common subunits including microfarads (µF) and picofarads (pF). The capacitance value indicates the amount of charge a capacitor can store.

2. Tolerance Levels

Tolerance levels indicate the permissible variation in capacitance from the specified value. Common tolerances for ceramic capacitors range from ±5% to ±20%, depending on the class and application.

B. Voltage Rating

1. Definition and Importance

The voltage rating of a ceramic capacitor indicates the maximum voltage the capacitor can withstand without breaking down. Exceeding this rating can lead to catastrophic failure.

2. Derating Guidelines

It is advisable to derate capacitors by 20-50% of their rated voltage in practical applications to enhance reliability and longevity.

C. Temperature Coefficient

1. Explanation of Temperature Coefficients (X7R, C0G, etc.)

Temperature coefficients describe how capacitance changes with temperature. For example, C0G capacitors have a temperature coefficient of ±30 ppm/°C, while X7R capacitors can vary by ±15% over a temperature range of -55°C to +125°C.

2. Impact on Performance

The temperature coefficient significantly impacts the performance of capacitors in varying environmental conditions. Choosing the right coefficient is crucial for maintaining circuit stability.

D. Size and Form Factor

1. Common Package Types (0805, 1206, etc.)

Ceramic capacitors come in various package sizes, with 0805 and 1206 being among the most common. The size affects the capacitance value, voltage rating, and application suitability.

2. Influence on Circuit Design

The form factor of a capacitor can influence PCB layout and design. Smaller capacitors allow for more compact designs, while larger capacitors may be necessary for higher capacitance values.

IV. Performance Characteristics

A. Frequency Response

1. Impedance and Reactance

Ceramic capacitors exhibit frequency-dependent impedance and reactance. At higher frequencies, the impedance decreases, making them suitable for high-frequency applications.

2. Self-Resonant Frequency

The self-resonant frequency is the frequency at which the capacitor's reactance becomes zero. Beyond this frequency, the capacitor behaves more like an inductor, which can affect circuit performance.

B. Dielectric Loss

1. Definition and Measurement

Dielectric loss refers to the energy lost as heat in a capacitor due to the dielectric material's properties. It is measured using the dissipation factor (DF) or equivalent series resistance (ESR).

2. Impact on Efficiency

High dielectric loss can lead to reduced efficiency in circuits, especially in high-frequency applications. Selecting capacitors with low dielectric loss is essential for optimal performance.

C. Aging Effects

1. Mechanisms of Aging

Ceramic capacitors can experience aging effects, where capacitance values change over time due to material degradation. This is particularly relevant for Class 2 capacitors.

2. Mitigation Strategies

To mitigate aging effects, manufacturers often recommend using capacitors with higher voltage ratings or selecting Class 1 capacitors for critical applications.

V. Applications of Ceramic Capacitors

A. Consumer Electronics

1. Smartphones and Tablets

Ceramic capacitors are widely used in smartphones and tablets for decoupling and filtering applications, ensuring stable power supply and signal integrity.

2. Home Appliances

In home appliances, ceramic capacitors are used for motor control, power supply circuits, and noise filtering, enhancing performance and reliability.

B. Automotive Industry

1. Electric Vehicles

With the rise of electric vehicles, ceramic capacitors are essential for power management, energy storage, and signal processing in various automotive systems.

2. Safety Systems

Ceramic capacitors are critical in automotive safety systems, including airbag deployment and anti-lock braking systems, where reliability is paramount.

C. Industrial Applications

1. Automation and Control Systems

In industrial automation, ceramic capacitors are used in control systems for filtering and decoupling, ensuring stable operation of machinery.

2. Power Supply Circuits

Ceramic capacitors are integral to power supply circuits, providing energy storage and filtering to maintain voltage stability.

VI. Selection Criteria for Ceramic Capacitors

A. Application Requirements

1. Voltage and Capacitance Needs

When selecting ceramic capacitors, it is essential to consider the specific voltage and capacitance requirements of the application to ensure optimal performance.

2. Environmental Considerations

Environmental factors, such as temperature and humidity, can affect capacitor performance. Selecting capacitors with appropriate temperature coefficients is crucial.

B. Manufacturer Specifications

1. Quality Standards

Choosing capacitors from reputable manufacturers ensures adherence to quality standards, which is vital for reliability in critical applications.

2. Reliability Ratings

Reliability ratings, such as lifetime expectancy and failure rates, should be considered when selecting capacitors for long-term applications.

C. Cost Considerations

1. Budget Constraints

Cost is often a significant factor in component selection. Balancing performance and cost is essential for project feasibility.

2. Long-term Value

Investing in high-quality capacitors may lead to lower maintenance costs and improved reliability, providing long-term value.

VII. Future Trends in Ceramic Capacitor Technology

A. Advancements in Materials

1. New Dielectric Materials

Research into new dielectric materials aims to enhance capacitance values and stability, leading to improved performance in various applications.

2. Miniaturization Trends

The trend towards miniaturization in electronics drives the development of smaller, more efficient ceramic capacitors, enabling more compact designs.

B. Market Demand and Growth

1. Emerging Applications

As technology evolves, new applications for ceramic capacitors are emerging, particularly in fields like renewable energy and IoT devices.

2. Global Market Trends

The global market for ceramic capacitors is expected to grow, driven by increasing demand in consumer electronics, automotive, and industrial sectors.

VIII. Conclusion

A. Recap of Key Points

Ceramic capacitors are vital components in modern electronics, with various types and parameters that influence their performance. Understanding these parameters is essential for selecting the right capacitor for specific applications.

B. Importance of Understanding Parameters

Knowledge of capacitance values, voltage ratings, temperature coefficients, and other parameters allows engineers to make informed decisions, ensuring optimal circuit performance.

C. Final Thoughts on the Role of Ceramic Capacitors in Modern Electronics

As technology continues to advance, the role of ceramic capacitors will remain critical in driving innovation and enhancing the performance of electronic devices across various industries.

IX. References

A. Academic Journals

1. "Dielectric Properties of Ceramic Capacitors" - Journal of Electronic Materials

2. "Advancements in Capacitor Technology" - IEEE Transactions on Industrial Electronics

B. Industry Reports

1. "Global Ceramic Capacitor Market Analysis" - Market Research Future

2. "Trends in Electronic Components" - Electronics Weekly

C. Manufacturer Datasheets

1. Murata Manufacturing Co., Ltd. - Ceramic Capacitor Datasheets

2. KEMET Corporation - Capacitor Product Catalog

This blog post provides a detailed overview of ceramic capacitors, their types, parameters, applications, and future trends, serving as a valuable resource for engineers and designers in the electronics industry.