What is a high-voltage capacitor?

What is a High-Voltage Capacitor?

I. Introduction

High-voltage capacitors are essential components in various electrical and electronic systems, designed to store and release electrical energy at voltages exceeding 1,000 volts. These capacitors play a crucial role in applications ranging from power electronics to medical equipment, ensuring efficient energy management and signal processing. In this article, we will explore the fundamentals of high-voltage capacitors, their characteristics, applications, design considerations, challenges, and future trends.

II. Understanding Capacitors

A. Basic Principles of Capacitors

1. **Definition and Function**: A capacitor is a passive electronic component that stores electrical energy in an electric field. It consists of two conductive plates separated by an insulating material known as a dielectric. When a voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy.

2. **Components of a Capacitor**: The primary components of a capacitor include the two conductive plates, the dielectric material, and the terminals that connect the capacitor to a circuit. The capacitance, measured in farads, indicates the capacitor's ability to store charge.

B. Types of Capacitors

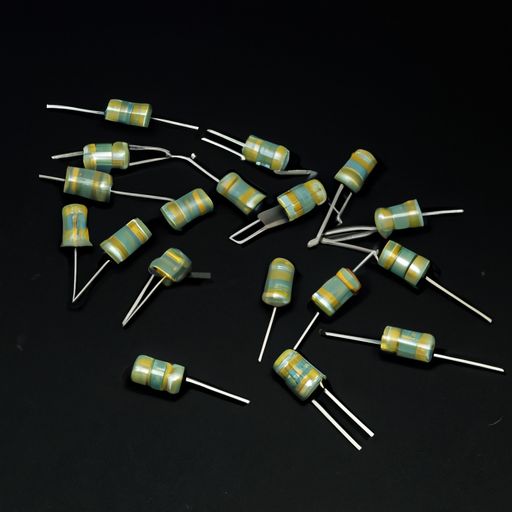

Capacitors come in various types, each suited for specific applications:

1. **Electrolytic Capacitors**: These capacitors use an electrolyte as one of the plates, allowing for high capacitance values in a relatively small size. They are polarized, meaning they must be connected in the correct direction in a circuit.

2. **Ceramic Capacitors**: Made from ceramic materials, these capacitors are non-polarized and are commonly used in high-frequency applications due to their stability and low losses.

3. **Film Capacitors**: These capacitors use a thin plastic film as the dielectric. They are known for their reliability and stability, making them suitable for various applications, including audio and power electronics.

4. **Tantalum Capacitors**: Tantalum capacitors are known for their high capacitance-to-volume ratio and stability. They are often used in compact electronic devices.

C. Voltage Ratings and Their Significance

The voltage rating of a capacitor indicates the maximum voltage it can handle without breaking down. Exceeding this rating can lead to capacitor failure, which may cause circuit damage or safety hazards. High-voltage capacitors are specifically designed to operate safely at elevated voltages, making them critical in high-power applications.

III. High-Voltage Capacitors

A. Definition and Characteristics

1. **Voltage Ratings Above 1,000 Volts**: High-voltage capacitors are defined as those with voltage ratings exceeding 1,000 volts. These capacitors are engineered to withstand the stresses associated with high-voltage applications.

2. **Physical Size and Construction**: High-voltage capacitors are typically larger than standard capacitors due to the need for thicker dielectric materials and robust construction to prevent breakdown. Their design often includes features to enhance insulation and heat dissipation.

B. Materials Used in High-Voltage Capacitors

1. **Dielectric Materials**: The choice of dielectric material is critical in high-voltage capacitors. Common materials include polypropylene, polyester, and ceramic, each offering different properties in terms of dielectric strength, temperature stability, and loss characteristics.

2. **Conductive Materials**: The conductive plates are usually made from aluminum or tantalum, chosen for their conductivity and resistance to corrosion. The selection of materials impacts the capacitor's performance, reliability, and lifespan.

C. Comparison with Standard Capacitors

High-voltage capacitors differ from standard capacitors in several ways, including their construction, materials, and intended applications. While standard capacitors may suffice for low-voltage applications, high-voltage capacitors are specifically designed to handle the unique challenges posed by elevated voltages.

IV. Applications of High-Voltage Capacitors

High-voltage capacitors find applications across various industries, including:

A. Power Electronics

1. **Inverters and Converters**: High-voltage capacitors are essential in inverters and converters, which are used to convert DC to AC power and vice versa. They help smooth out voltage fluctuations and store energy for efficient power delivery.

2. **Energy Storage Systems**: In renewable energy systems, such as solar and wind, high-voltage capacitors are used to store energy generated during peak production times, ensuring a stable power supply.

B. Industrial Applications

1. **Motor Drives**: High-voltage capacitors are used in motor drives to improve efficiency and performance. They help manage power factor correction, reducing energy losses in industrial motors.

2. **Power Factor Correction**: In industrial settings, high-voltage capacitors are employed to correct power factor issues, improving the efficiency of electrical systems and reducing utility costs.

C. Medical Equipment

1. **MRI Machines**: High-voltage capacitors are critical in MRI machines, where they help generate the strong magnetic fields required for imaging.

2. **X-ray Machines**: In X-ray machines, high-voltage capacitors store energy needed to produce X-rays, ensuring precise and reliable operation.

D. Telecommunications

1. **Signal Processing**: High-voltage capacitors are used in telecommunications for signal processing, helping to filter and stabilize signals in communication systems.

2. **RF Applications**: In radio frequency (RF) applications, high-voltage capacitors are essential for tuning circuits and maintaining signal integrity.

V. Design Considerations

A. Selecting the Right High-Voltage Capacitor

1. **Voltage Rating**: When selecting a high-voltage capacitor, it is crucial to choose one with a voltage rating that exceeds the maximum voltage expected in the application to ensure safety and reliability.

2. **Capacitance Value**: The capacitance value must be appropriate for the specific application, balancing energy storage needs with physical size and cost.

3. **Temperature and Environmental Factors**: Consideration of the operating environment is essential, as temperature fluctuations and humidity can affect capacitor performance and lifespan.

B. Safety Considerations

1. **Handling and Installation**: High-voltage capacitors can pose significant safety risks if not handled properly. Proper training and safety protocols are essential during installation and maintenance.

2. **Failure Modes and Risks**: Understanding potential failure modes, such as dielectric breakdown or thermal runaway, is critical for ensuring safe operation and preventing accidents.

VI. Challenges and Limitations

A. Size and Weight Constraints

High-voltage capacitors tend to be larger and heavier than their low-voltage counterparts, which can pose challenges in applications where space and weight are critical factors.

B. Cost Factors

The materials and manufacturing processes used in high-voltage capacitors can make them more expensive than standard capacitors. This cost factor can limit their use in certain applications.

C. Reliability and Lifespan Issues

High-voltage capacitors must be designed for reliability, as failure can lead to significant downtime and safety hazards. Ensuring a long lifespan requires careful selection of materials and design considerations.

VII. Future Trends in High-Voltage Capacitors

A. Advances in Materials Science

Ongoing research in materials science is leading to the development of new dielectric materials that offer improved performance, higher voltage ratings, and reduced size.

B. Innovations in Design and Manufacturing

Advancements in manufacturing techniques, such as 3D printing and nanotechnology, are enabling the production of more efficient and compact high-voltage capacitors.

C. Emerging Applications in Renewable Energy

As the demand for renewable energy sources grows, high-voltage capacitors will play an increasingly important role in energy storage systems, helping to stabilize power grids and improve energy efficiency.

VIII. Conclusion

High-voltage capacitors are vital components in modern technology, enabling efficient energy management and reliable operation in various applications. Their unique characteristics and capabilities make them indispensable in power electronics, industrial systems, medical equipment, and telecommunications. As technology continues to evolve, high-voltage capacitors will remain at the forefront of innovation, driving advancements in energy storage and management. Understanding their importance and functionality is essential for anyone involved in electrical engineering or related fields.

IX. References

For further reading and exploration of high-voltage capacitors, consider the following resources:

1. "Capacitors: Technology and Trends" - An overview of capacitor technology and its applications.

2. "High-Voltage Capacitors: Design and Applications" - A comprehensive guide to high-voltage capacitor design and usage.

3. Academic papers and industry reports on high-voltage capacitors, available through engineering databases and journals.